Atom Probe Tomography

Grain Size in Nanocrystalline Copper

This example demonstrates the multifaceted and diverse characterization facility that is ScopeM. We present metallic nano-printed pillars that were made by a cutting-edge automated technique developed in D-MATL’s Laboratory for Nanometallurgy group called electrohydrodynamic redox printing.

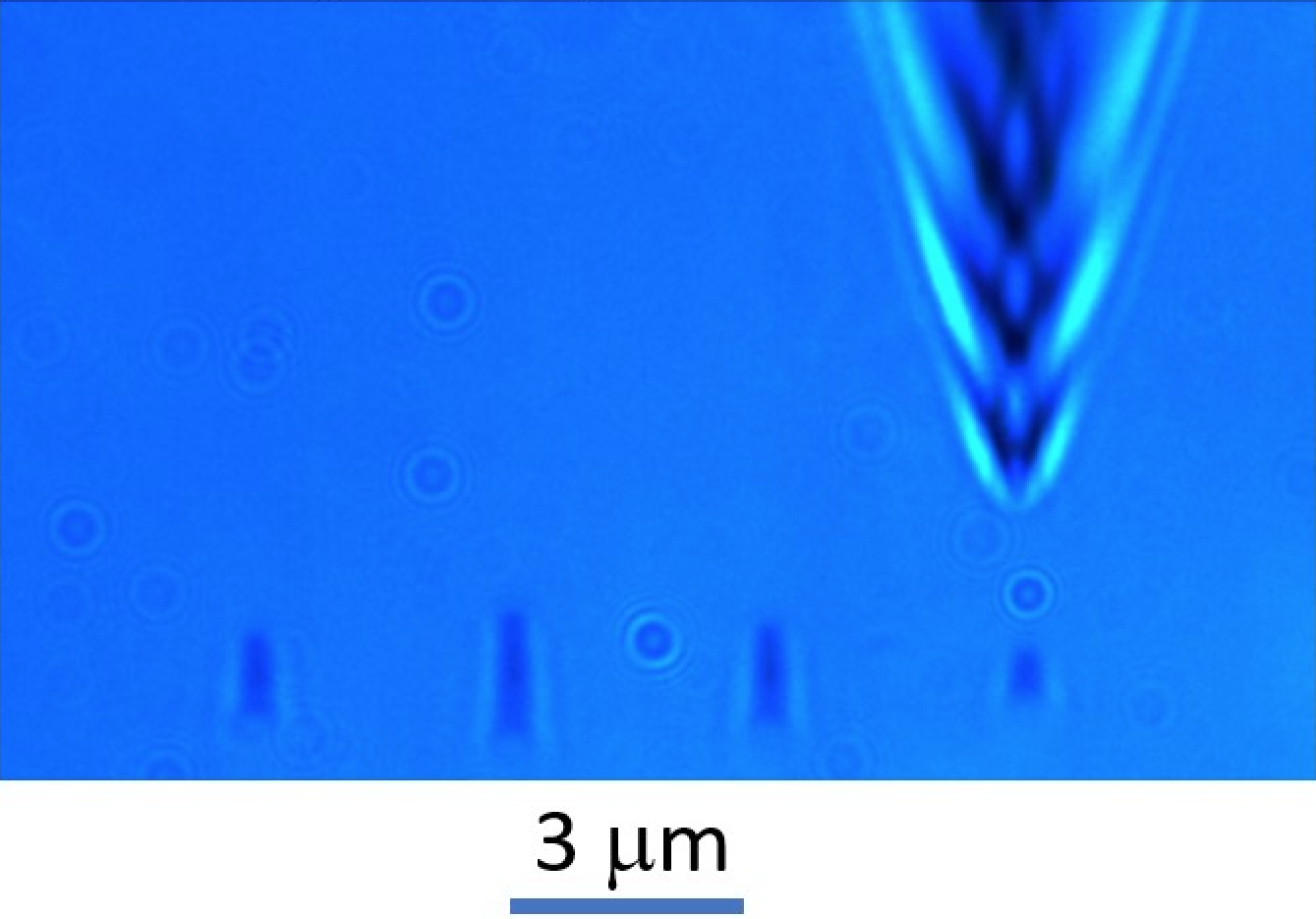

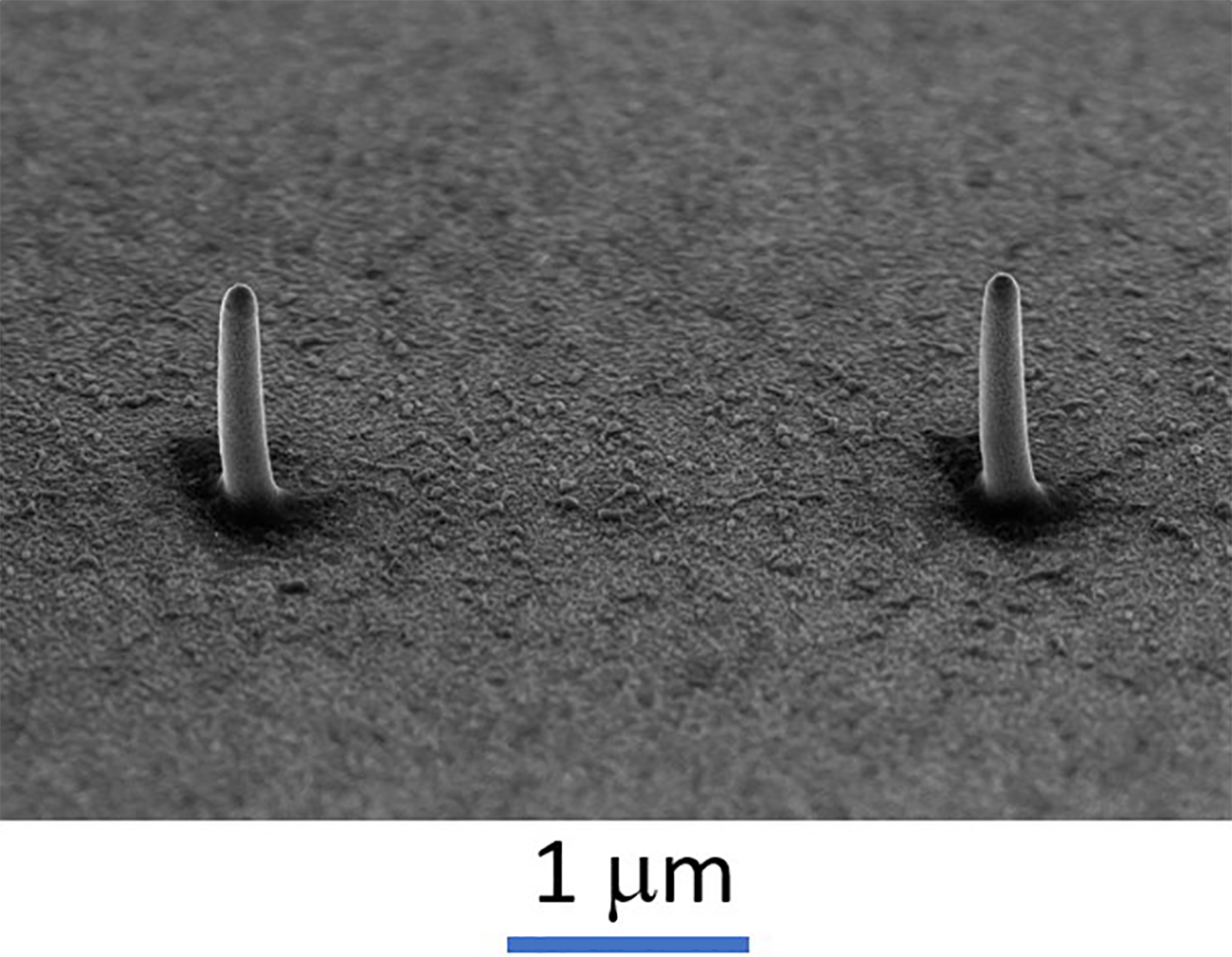

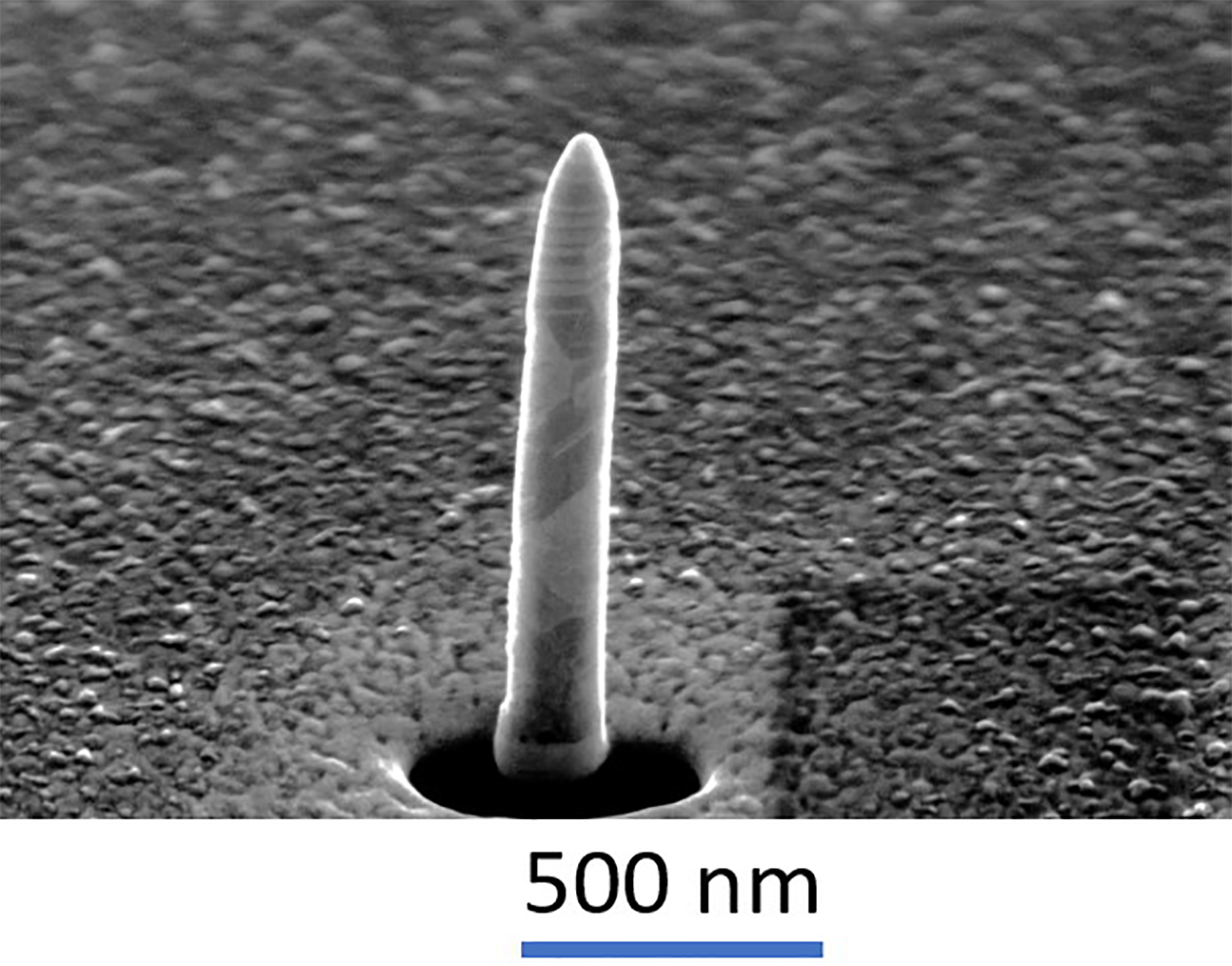

PhD candidate Maxence Menétrey first imaged the pillars with 465 nm wavelength photons (in argon gas) in Prof. Spolenak’s lab during the printing process (see figure, nozzle to pillar distance 7.5 μm), followed by characterizing them applying multiple electron and ion beams at increasing magnifications.

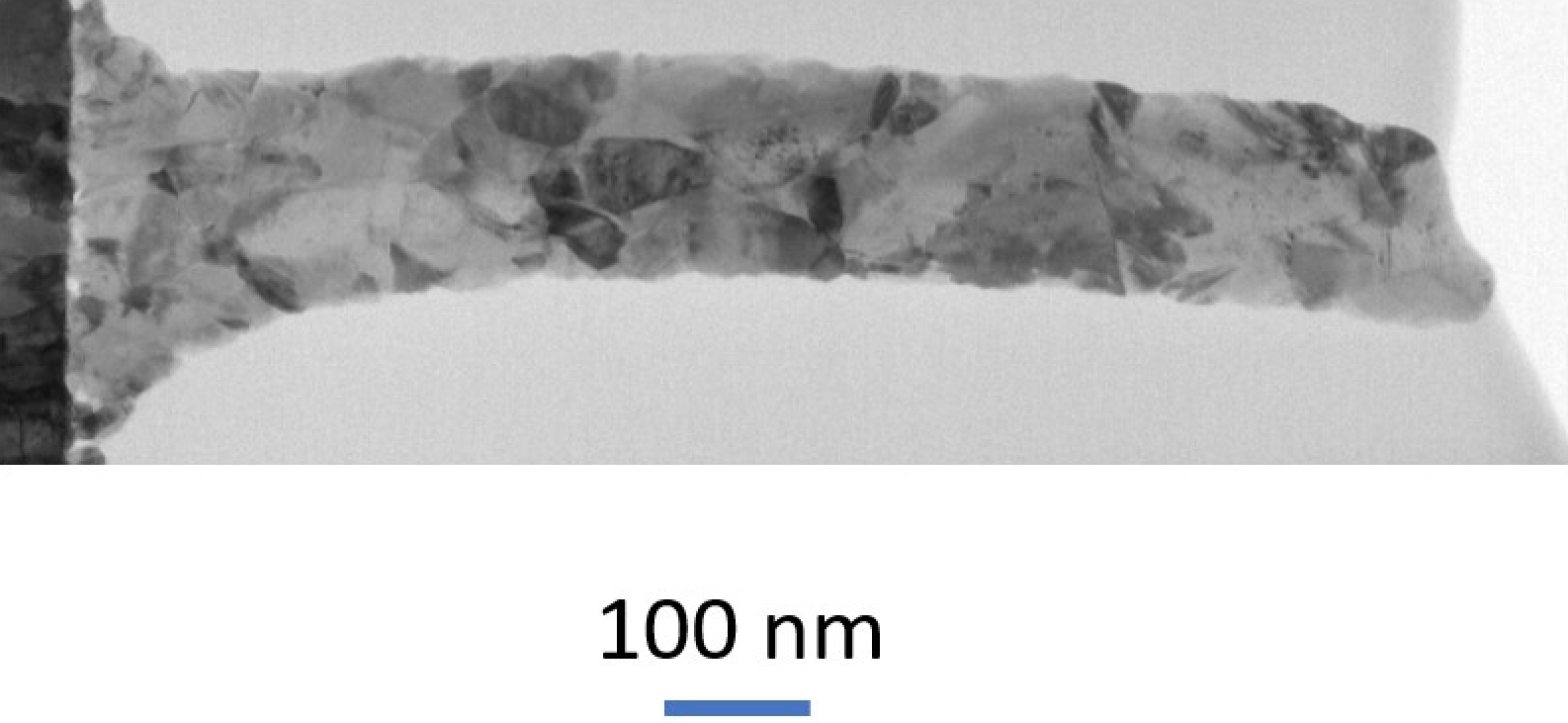

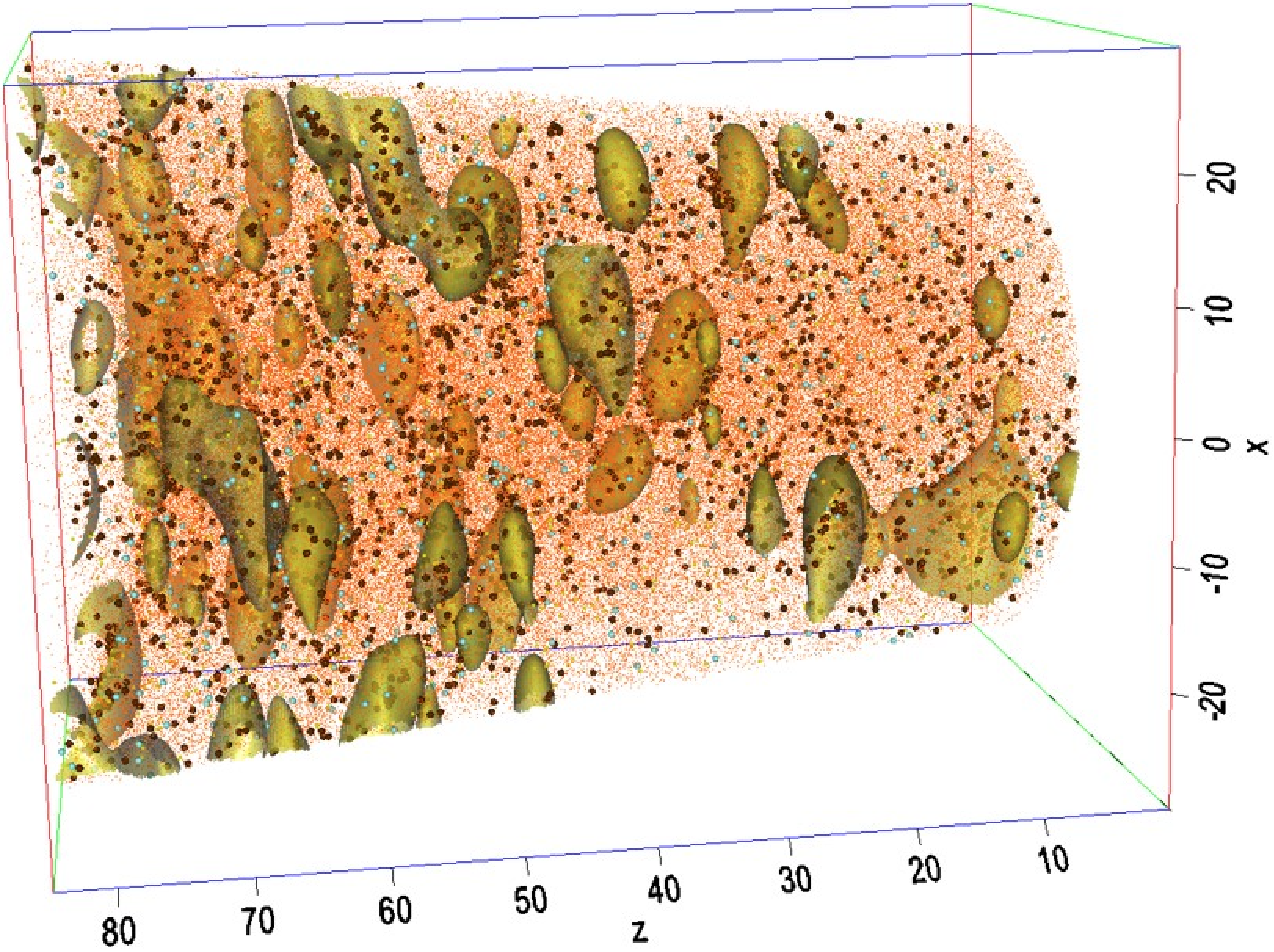

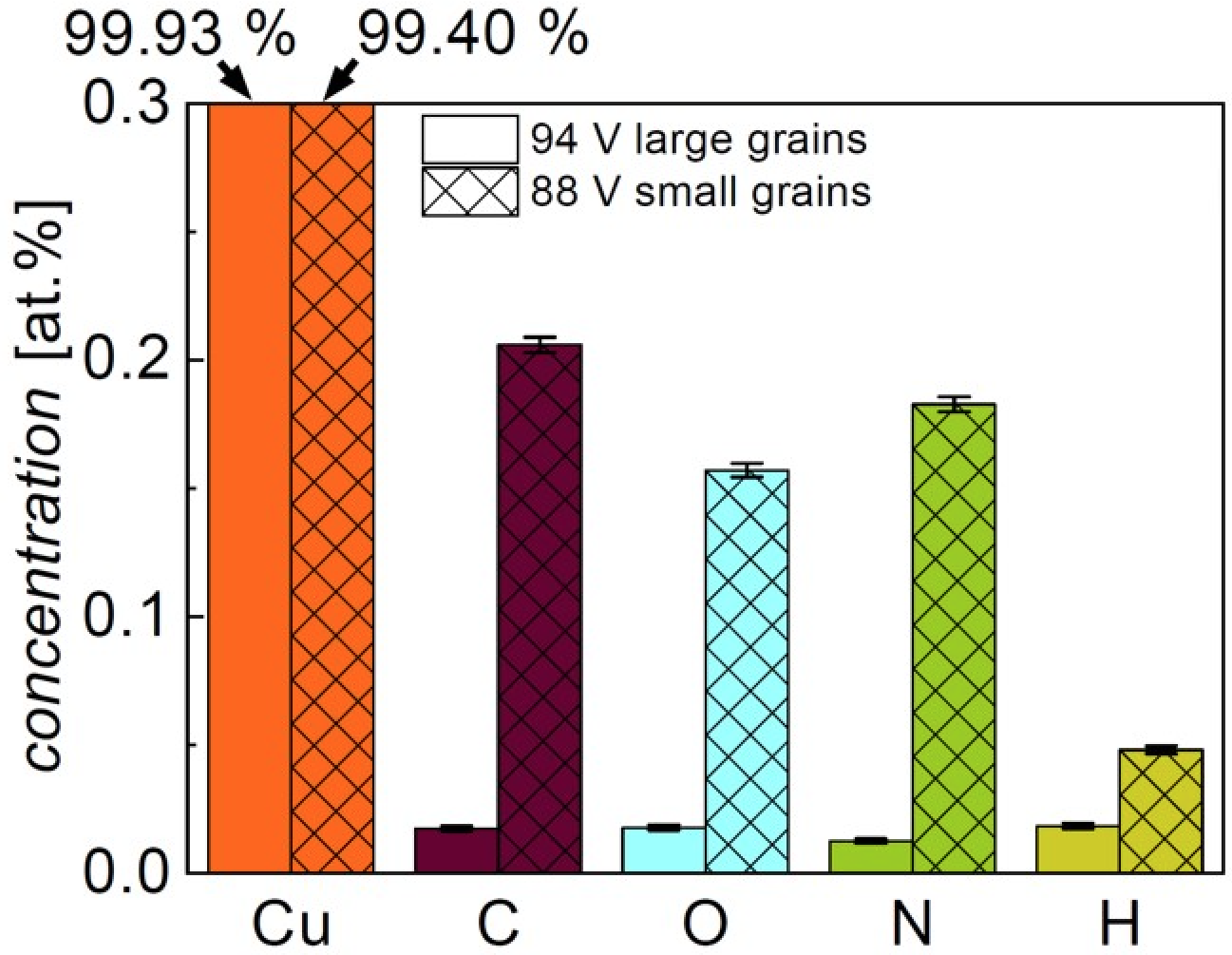

This combination of techniques - spanning over 9 orders of magnitude in spatial resolution - in a correlative fashion, enabled the quantification of modulations in microstructures – simply due to a difference in 6 V during printing – corresponding strength (mechanical properties) and the 3-dimensional chemical distributions (to < 0.1 at.% accuracy, see figure) within the sub-micrometer printed pillars.

References:

Reiser, A., et al., Multi-metal electrohydrodynamic redox 3D printing at the submicron scale. Nat. Commun. 10, 1853 (2019). external page DOI: 10.1038/s41467-019-09827-1

Menetrey, M., et al., Targeted Additive Micromodulation of Grain Size in Nanocrystalline Copper Nanostructures by Electrohydrodynamic Redox 3D Printing. Small, vol. 18: no. 51, pp. 2205302, Weinheim: Wiley-VCH (2022). external page DOI: 10.1002/smll.202205302